Replacing electrolytic capacitors is one of the most common ways to repair (and maintain) vintage electronic gear. This article will explain what these capacitors do and discuss a few different approaches for replacing them.

What are Electrolytic Filter Capacitors?

When a new piece of vintage gear shows up in my shop – the first thing that usually gets checked (and replaced) are the large electrolytic capacitors in the power supply stage. Usually, these are large silver multi-section can capacitors. In older gear or smaller tube radios, these filter caps are sometimes large multi-section axial wax and paper caps.

In older gear or smaller tube radios, these filter caps are sometimes large multi-section axial wax and paper caps.

What Do Filter Caps Do?

These large electrolytic capacitors in the power supply stage are known as filter caps – because their primary job is to filter the rectified voltage to feed different stages in the circuit a clean and constant supply of DC voltage.

Why Do They Need To Be Replaced?

Electrolytic capacitors can drift in value over time as the electrolyte inside dissipates. Increased ESR (Equivalent Series Resistance) can gradually turn a capacitor into a resistor. Capacitors can also “leak” DC current and voltage – throwing bias off in different parts of the circuit which can affect the performance of tube and transistor circuits. Additionally, the hot temperatures inside a tube amp shorten their lifetime. In extreme cases, high energy surges can crack the dielectric material and cause complete failure – resulting in direct shorts.

While some repair techs will correctly tell you that electrolytic capacitors have some ability to “self heal” and “re-form” after years of abuse or disuse – There is no way to replace the dried out electrolyte. While re-forming capacitors may prolong their useful life temporarily – the only way to ensure that these important components will continue to function properly is to replace them.

When Should I Replace Them?

Some techs will advise to wait until the component fails before you replace it. I like taking a preventative approach since capacitor failure can be harmful to other components as well. My personal rule of thumb is to replace all electrolytics in gear that was produced before 1970.

New Production Multi-Section Can Capacitors

Large can capacitors are still manufactured and available for purchase through many online sources. Purists who wish to retain the “look” of vintage equipment may opt to use these.

There are many options for multi-section can caps from manufacturers such as:

- JJ Electronics (Slovak Republic)

- F&T (Germany)

- Hayseed Hamfest (US)

- CE Manufacturing (US)

If you’re a vintage nerd like me, you can’t help but be charmed by CE Manufacturing’s use of original Mallory equipment to manufacture new production capacitors to the original Mallory specification.

New Production Axial Capacitors

Another option to consider when replacing electrolytic capacitors in your gear is to purchase modern axial capacitors with high voltage ratings.

- Vishay / Sprague (US Multi-national)

- Illinois Capacitor (US Division of Cornell-Dubilier)

- Nichicon (Japan)

Axial caps in particular are useful in power supplies constructed on turret boards, common on vintage guitar amps.

Problems With Using Axial and Multi-Section Capacitors

The new production axial and multi-section caps are great – I’m sure glad there are still many options out there. However – consider one other factor: price.

A can capacitor from CE Manufacturing with four sections (40/20/20/20) can cost $40.90. A similar JJ can capacitor costs $16.95.

After researching options for my many projects, I got tired of paying $15-50 to replace every can cap. And if a project had more than one of them, it got very expensive. One old piece of test gear I rebuilt had four of them! The new caps cost more than the equipment itself.

I then started noticing something about many of these can capacitors – for the most part, they are based on old technology and do not have the high specifications of modern options.

- The tolerance in capacitance value is wide ( -20% / +80% or -10% / +50%)

- The temperature rating is often low (55 – 70 degrees Celsius)

- The load life is often short (rated at 1000-2000 hours)

I realize that in practical terms, any capacitor you install will likely perform fine for the next 20-30 years. For most of us, that’s plenty of time. Compared to inkjet printers that run out of ink every 5 prints – this is truly incredible performance for a single component!

But if you’re looking for high performance on a budget, you get creative – and that’s what led me to an alternate solution with higher performance specifications and lower cost.

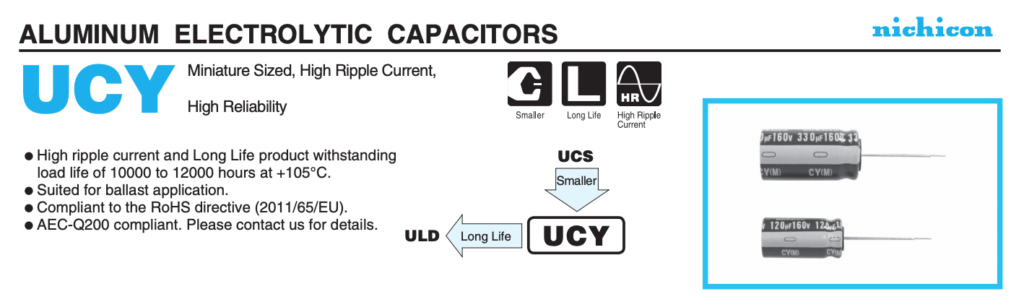

Nichicon UCY Capacitors

The Nichcon UCY line of capacitors (PDF Datasheet) offers several desirable performance boosts:

- Rated for high temperatures (+105 degrees Celsius)

- Rated for long life (load life of 10,000 – 12,000 hours)

- Tolerance is a little tighter at ±20%

- Rated to handle high ripple current

This capacitor is also quite affordable. A 22 µF UCY cap is only $1.71 on Mouser. Since Mouser offers discounts on quantity, you can get the price even lower by buying in bulk. For example, buying 10 will bring the price down to $1.36 each.

This capacitor is also quite affordable. A 22 µF UCY cap is only $1.71 on Mouser. Since Mouser offers discounts on quantity, you can get the price even lower by buying in bulk. For example, buying 10 will bring the price down to $1.36 each.

The only issue? They’re radial caps. How do you make them work to replace a multi-section can cap or axial cap?

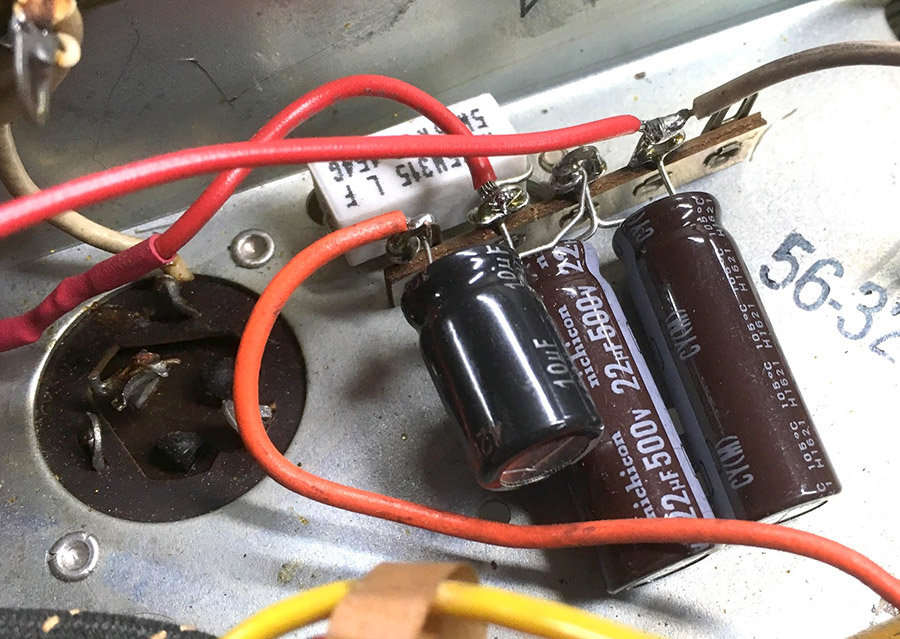

Mounting Radial Caps on a Terminal Strip

Terminal strips are commonly used in point to point wiring and offer a solid base to mount radial caps to that can be bolted or riveted directly to the chassis – thus also providing a chassis ground.

Simply disconnect all leads from the old can cap and route them to the terminal strip instead. I’ll usually leave the can cap in for “looks” – if fully disconnected it will do no harm. If you have the room underneath, this is now my preferred way of rebuilding power supplies on vintage gear. When space is super tight – I’ll spring for a new production can cap.

If you have the room underneath, this is now my preferred way of rebuilding power supplies on vintage gear. When space is super tight – I’ll spring for a new production can cap.

When replacing electrolytic capacitors in your vintage gear, which method do you prefer? Let me know in the comments.